Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

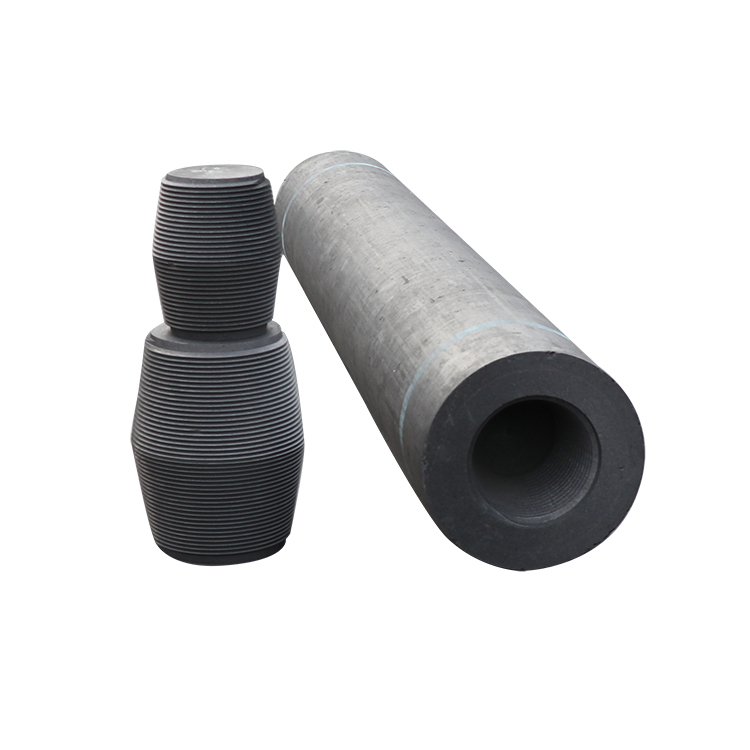

Graphite electrode classification: ordinary power graphite electrode (RP); High power graphite electrode (HP); Quasi-ultra-high power graphite electrode (SHP); Ultra high power graphite electrode (UHP).

(1) For electric arc steelmaking furnace

Graphite electrode materials can be mainly used for electric furnace steelmaking. Electric furnace steelmaking is conducted using graphite electrodes.

(2) For mineral heating electric furnace

Used to produce mainly iron furnace ferroalloys, pure silicon, yellow phosphorus, calcium carbide and matte, which is characterized by the lower part of the conductive electrode buried in the charge, so in addition to the arc between the plate and the charge to generate heat, the current through the charge by the resistance of the charge also generate heat.

(3) For resistance furnaces

In the production process, the graphitization furnace for graphite material products, the melting kiln and production of melting technology glass, and the electric furnace for silicon carbide are all resistance furnaces, and the material management in the furnace is not only a heating resistance, but also the object of heating.

(4) A large number of graphite electrode blanks are also used for processing into various crucibles, graphite boats, hot die casting molds and vacuum electric furnace heating bodies and other shaped products.

It should also be noted that in the graphite material including graphite electrode, graphite mold and graphite crucible three kinds of high temperature composite materials in the graphite material, at high temperature three graphite materials, graphite is easy to oxidize combustion reaction, thereby improving the porosity of the carbon layer on the surface of the plastic material, the structure is loose.

The working current is introduced into the furnace, and the strong current at the lower end of the electrode can affect the arc discharge through these gas environments, and the heat generated by the arc is used for smelting. The size of the capacitance, equipped with graphite electrodes having different diameters, can be used continuously, against the electrode joint between the electrodes. Graphite used in steelmaking as an electrode material accounts for about 70-80% of the total amount of graphite electrodes in China.

Recent Posts

undefined

Quote Now

Quote Now