Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

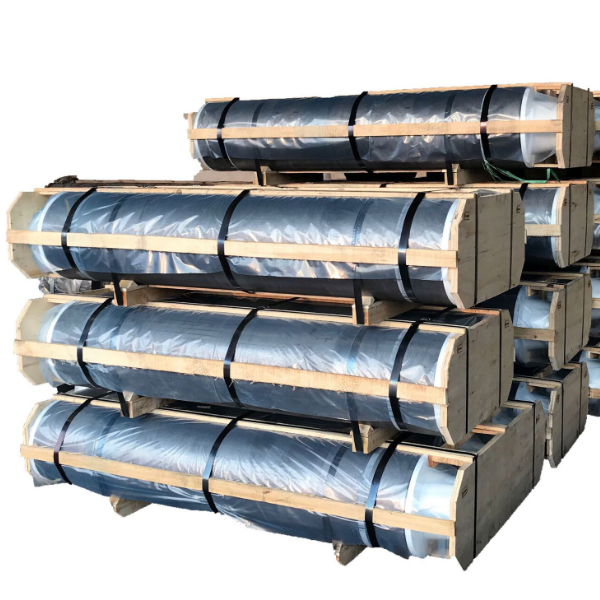

(1) The production cycle is long. The production cycle of ordinary power UHP Graphite Electrodes on sales is about 45 days, the production cycle of ultra-high power graphite electrodes is more than 70 days, and the production cycle of UHP Graphite Electrodes on sales joints that require multiple dipping is longer.

(2) High energy consumption. The production of 1t of ordinary power UHP Graphite Electrodes on sales needs to consume about 6000kW h of electricity, thousands of cubic meters of gas or natural gas, and about 1t of metallurgical coke particles and metallurgical coke powder.

(3) There are many production processes. The production process of UHP Graphite Electrodes on sales includes raw material calcination, crushing and grinding, batching, kneading, molding, roasting, impregnation, graphitization, and mechanical processing. Its production requires many special mechanical equipment and kilns with special structures, the construction investment is relatively large, and the investment recovery period is relatively long.

Through the above introduction and analysis of the Production Features of UHP Graphite Electrodes on sales, hope it helps you.

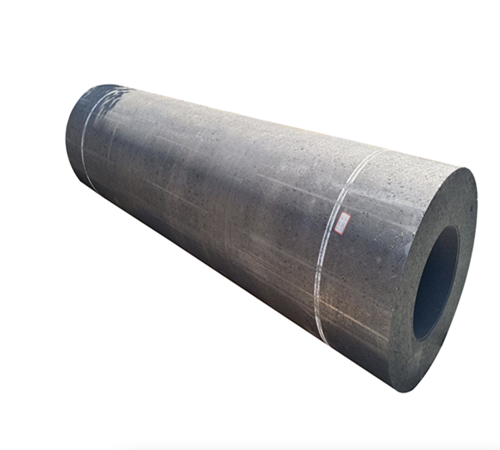

Resource selection: The production of ultra-high voltage graphite electrodes requires the use of high-quality petroleum coke and needle coke as raw materials. These carbonaceous materials have excellent thermal and electrical conductivity and have high mechanical strength.

Production process: The production process of ultra-high voltage graphite electrodes includes several key stages. First, the raw materials are crushed and screened, then mixed with coal pitch, extruded or molded to form the electrode shape, the shaped electrode is calcined in a controlled environment to remove volatile compounds, and finally graphitized at high temperatures to improve performance.

High density and low resistivity: Ultra-high voltage graphite electrodes are known for their high volume density and low resistivity. This ensures efficient and consistent performance during electric arc furnace steelmaking, thereby increasing productivity and energy efficiency.

Mechanical Strength and Structural Integrity: UHV graphite electrodes are able to withstand high temperatures and mechanical stress. They have high flexural strength and are resistant to breakage, bending and erosion, ensuring a longer service life and reduced downtime and maintenance costs.

Good antioxidant properties: Ultra-high voltage graphite electrodes are specially formulated to have excellent antioxidant properties and high-temperature chemical reaction resistance. This antioxidant property reduces electrode wear and extends service life.

Dimensional control accuracy: UHV graphite electrodes have precise dimensional control during the production process to meet the specific requirements of different electric arc furnace configurations. This precise dimensional control ensures optimal performance and reliable operation of the electrodes in the steel manufacturing process.

Quality Assurance: The production process of ultra-high voltage graphite electrodes undergoes strict quality control and is regularly monitored and tested. Quality parameters such as density, resistivity, flexural strength, dimensions and oxidation resistance are tested to comply with international standards and customer expectations.

Recent Posts

undefined

Quote Now

Quote Now