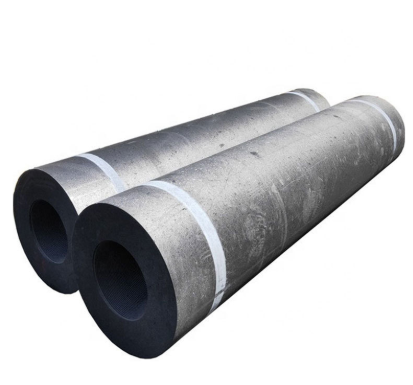

Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

RP (Regular Power) graphite electrodes fromChina are widely used in various applications such as electric arc furnaces for steel production, smelting processes, and other high-temperature industrial applications. These electrodes are manufactured using a combination of high-quality petroleum coke and coal tar pitch.

The primary raw material, petroleum coke, is carefully selected to ensure high carbon content and low levels of impurities. It undergoes various processes such as crushing, calcining, and blending to achieve the desired properties. The petroleum coke used in RP graphite electrodes is typically of medium sulfur content and particle size, offering good electrical conductivity and mechanical strength.

Coal tar pitch, a byproduct of coal tar distillation, is used as the binder for the petroleum coke particles. It is mixed and heated to form a paste, which is then extruded into the desired electrode shape. The coal tar pitch binder provides excellent adhesion and stability to the electrode structure, enabling it to withstand the high temperatures and intense electrical currents encountered during operations.

China has a well-established graphite electrode manufacturing industry and is known for its advanced production technology and quality control measures. Chinese RP graphite electrodes are manufactured using state-of-the-art equipment, including advanced CNC machining centers and automated production lines. Stringent quality control procedures are implemented throughout the production process to ensure consistent and reliable electrode performance.

RP graphite electrodes from China are known for their good electrical conductivity, thermal resistance, and mechanical strength. They exhibit high oxidation resistance and can withstand extreme operating conditions, making them suitable for demanding applications. Furthermore, these electrodes offer excellent cost-effectiveness, making them a popular choice for manufacturers seeking reliable and competitively priced graphite electrodes.

RP graphite electrodes are typically composed of high-quality petroleum coke, needle coke (a premium grade of petroleum coke), and coal tar pitch as the binder. The ratio of these raw materials may vary depending on the manufacturer and specific requirements.

Petroleum coke is derived from oil refining processes and is a common carbonaceous material used in the production of graphite electrodes. It provides the primary source of carbon for the electrode.

Needle coke is a premium grade of petroleum coke that has a unique structure and properties. It contains a high percentage of aromatic hydrocarbons and has low levels of impurities, making it ideal for manufacturing high-quality graphite electrodes.

Coal tar pitch is a byproduct of the coal distillation process and acts as a binder for the raw materials. It helps to bind the particles of petroleum coke and needle coke together during the electrode production process. This binder gives the electrode its structural integrity and stability during high-temperature operations.

In addition to these main components, RP graphite electrodes may also contain small amounts of additives or modifiers to enhance their performance. These may include antioxidants, lubricants, and various carbonaceous materials. The composition and quality of the raw materials used in RP graphite electrodes play a crucial role in determining their electrical conductivity, thermal resistance, and overall performance in industrial applications.

RP graphite electrode stands for Regular Power graphite electrode. It is a type of graphite electrode commonly used in electric arc furnaces for steelmaking and other industrial processes.

Regular Power electrodes have a moderate electrical conductivity and thermal resistance. They are typically used in applications with lower current density and less demanding operating conditions compared to High Power (HP) or Ultra High Power (UHP) graphite electrodes.

RP graphite electrodes are suitable for melting and refining processes that do not require exceptionally high temperatures or extremely high current densities. They are commonly used in industries such as steelmaking for the production of carbon and alloy steels.

RP graphite electrodes are available in various diameters and lengths, depending on the requirements of the specific application and the size of the electric arc furnace.

Recent Posts

undefined

Quote Now

Quote Now