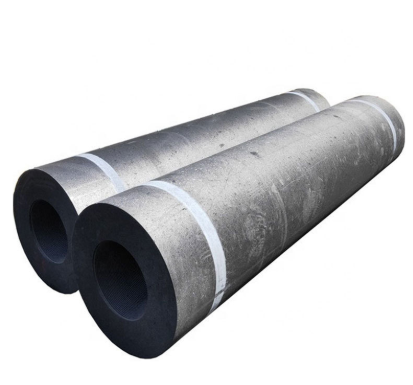

Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

Compared with granular and powdery calcined petroleum coke, needle-shaped calcined petroleum coke has the following advantages and disadvantages:

Advantage:

Excellent electrical and thermal conductivity: Needle-shaped calcined petroleum coke has a long and thin shape and high electrical and thermal conductivity. It is suitable for fields that require high electrical conductivity or high thermal conductivity.

Lower coke sulfur content: Needle-shaped calcined petroleum coke usually has a lower coke sulfur content during the production process, which helps reduce environmental pollution.

Good filling performance: The long and thin shape of needle-shaped calcined petroleum coke gives it good filling performance and is suitable for some applications that require filling materials.

Disadvantages:

Small specific surface area: Compared with granular and powdered cyclic petroleum coke, the specific surface area of needle-shaped calcined petroleum coke is relatively small, resulting in its lower activity in certain reactions.

Not easy to disperse evenly: The morphological characteristics of needle-shaped calcined petroleum coke determines that it is not easy to disperse evenly in liquid or solid, which may affect the performance and effect in certain applications.

Differences in application fields: Due to its special long and thin shape, needle-shaped calcined petroleum coke is mainly used in the following fields:

Carbon material processing: Needle-shaped calcined petroleum coke can be used to prepare high-strength carbon materials, such as needle-shaped graphite materials, which are used to make electrode materials, conductive materials, etc.

High-temperature materials: Needle-shaped calcined petroleum coke has good high-temperature stability and can be used as high-temperature refractory materials, ceramic materials, etc.

Flame retardant materials: Needle-shaped calcined petroleum coke can be used to make flame retardant materials to improve their flame retardant properties.

Carbon-carbon composite materials: Compounding needle-shaped calcined petroleum coke with other materials can be used to produce carbon-carbon composite materials with excellent electrical conductivity, mechanical properties and chemical stability.

In short, needle-shaped calcined petroleum coke is mainly used to manufacture products such as carbon materials, high-temperature materials, flame-retardant materials, and carbon-carbon composite materials. It has wide applications in the fields of power storage, high-temperature industry, and flame-retardant materials.

Recent Posts

undefined

Quote Now

Quote Now