Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

Graphite electrodes are essential components used in industries such as steelmaking, aluminum production, and electric arc furnaces. They are conductive rods made from graphite or a mixture of graphite and other materials. Here’s a brief overview of graphite electrodes:

Material: Graphite electrodes are primarily made from high-quality petroleum coke and needle coke. These raw materials are mixed with coal tar pitch and other additives, which are then processed and heated to transform into graphite electrodes.

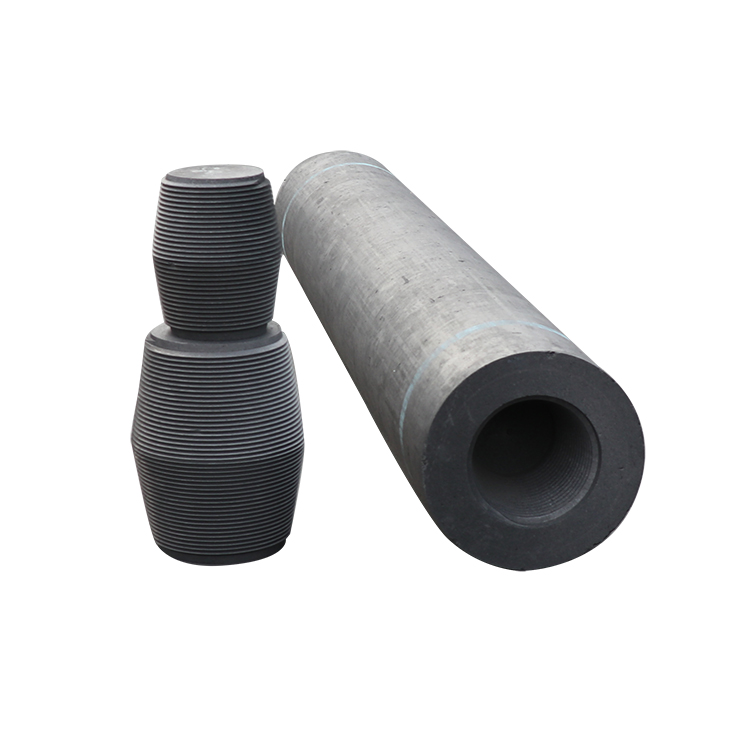

Size and Shapes: Graphite electrodes come in various sizes and shapes to suit different applications. The size of an electrode is determined by its diameter, while the length can vary depending on the specific requirements of the process. Common shapes include regular round electrodes, nipples, and various specialized shapes.

Conductivity: Graphite electrodes possess excellent electrical conductivity due to the unique structure of graphite. This high conductivity allows for the passage of a large amount of electric current, making graphite electrodes ideal for applications involving high-temperature electric arc reactions.

Resistance to Heat: Graphite electrodes have high thermal conductivity, allowing them to withstand extreme heat and transfer the heat efficiently during processes such as steelmaking. The ability to withstand high temperatures without deformation or disintegration is an essential characteristic of graphite electrodes.

Application: Graphite electrodes are primarily used in electric arc furnaces where they act as conductive elements to generate and maintain an electric arc. This arc produces the intense heat needed for melting and refining various materials, including steel scrap, iron ore, and aluminum scrap.

Grades: Different grades of graphite electrodes exist to meet the specific requirements of various applications. These grades differ in terms of electrical resistance, thermal conductivity, and mechanical strength. The choice of grade depends on factors such as the temperature of the process, the type of material being processed, and the desired quality of the final product.

Recycling: After use, graphite electrodes can be recycled by crushing and grinding them into a powder, which can then be used in the production of new graphite electrodes or other graphite-based products.

In summary, graphite electrodes play a crucial role in high-temperature industrial processes, providing efficient electrical conductivity and thermal resistance.

Recent Posts

undefined

Quote Now

Quote Now