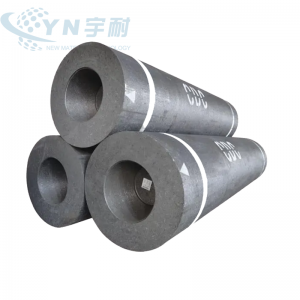

Brief introduction of graphite electrode

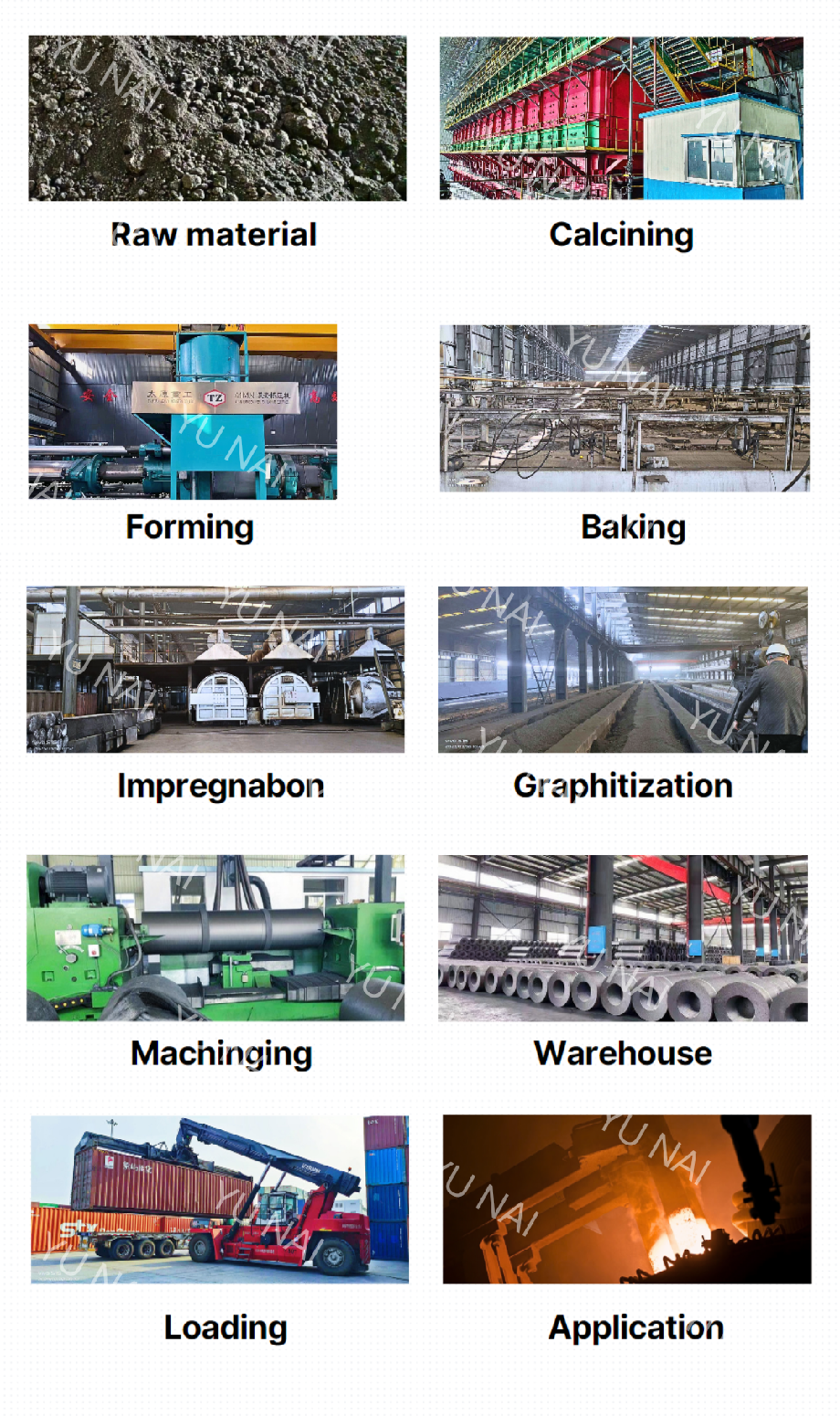

Graphite electrode refers to petroleum coke, pitch coke as aggregate, coal tar pitch as binder, and it is a kind of resistant electrode made by calcination of raw materials, crushing and grinding, batching, kneading, molding, roasting, impregnation, graphitization and mechanical machining. The High temperature graphite conductive material is called artificial graphite electrode (referred to as graphite electrode)

Graphite electrode classification

(1) Ordinary power graphite electrodes. It is allowed to use graphite electrodes with a current density lower than 17A/cm2, which are mainly used in ordinary power electric furnaces for steelmaking, silicon smelting, yellow phosphorus smelting, etc.

(2) Anti-oxidation coated graphite electrode. The graphite electrode coated with an anti-oxidation protective layer forms a protective layer that is both conductive and resistant to high-temperature oxidation, reducing electrode consumption during steelmaking.

(3) High-power graphite electrodes. Graphite electrodes with a current density of 18-25A/cm2 are allowed, and are mainly used in high-power electric arc furnaces for steelmaking.

(4) Ultra-high power graphite electrodes. Graphite electrodes with a current density greater than 25A/cm2 are allowed. Mainly used in ultra-high power steelmaking electric arc furnace

Production process of graphite electrode

Graphite electrode characteristics

1. High electrical and thermal conductivity;

2. High thermal vibration resistance and chemical stability;;

3. Good lubricity and durable;

4、Easy to process, high metal removalrate and low graphite lossduring EDM (electric spark)

5. The specific weight of graphite is 1/5 of copper, and graphite weighs 1/5 the weight ofcopper in the same volume. The large electrode made of copper is too heavy, which is badfor the accuracy of the EDM machine tool spindle during long-term electric spark. On thecontrary, graphite is very safe to handle.

6、Graphite has have a high processing speed that is 3-5 times faster than ordinary metals. Moreover,choosing appropriate-hardness tools and graphite can reduce the wear and tearof cutter and electrode.

Precautions for using graphite electrode

1.When using or storing the electrode, the users must be sure to avoid moisture dust, pollution

and collisions.

2.When the electrodes are carried by forklift trucks, their balance should be kept to prevent

slipping and breaking. The collision and overload are prohibited.

3.The electrodes should be stored in clean and dry places. When stored in the open-air storage,

they must be covered with tarpaulins.

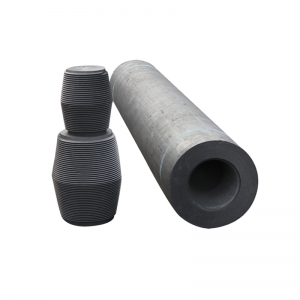

4.When connecting the electrodes, the users fifirst need to use compressed air to clean the thread of the electrode, then carefully rotate the contact into one end of the electrode and screw the

electrode hoist into the other end.The collision with the thread is not allowed.

5.When hiting up the electrode, the users should use a rotatable hook with a soft support pad on the bottom of the electrode nipple to prevent the damage on thread.

6.Before connecting the elecrodes, the users should clean the hole with compressed air.

7.Use an elastic hook hoist to lift the electrode to the furnace, then locate the center and move the electrode down slowly.

8.When the upper electrode is lowered 20-30mm away from the lower electrode, the users should use compressed air to clean the junction of the electrode.

9.Use special torque spanet to tighten the electrode according to the instructions, and use

mechanical,hydraulic of wind pressure equipment to tighten the electrode to a fifixed torque.

10.The electrode holder must be clamped within two white warming lines.The contact surface

between the holder and the electrode should be clean regularly to maintain good contact with

the electrode, and the cooling water of the holder must be prohibited from leaking.

11.Cover the top of the electrode to avoid oxidation and dust.

12.In order to avoid the breakage of electrodes, the users shall not place insulation blocks in the

furnace. The working current of the electrode should be compatible to the allowable working

current in the manual.

13.To avoid electrode breakage, place bulk material in lower part and small piece in upper part.

Quote Now

Quote Now