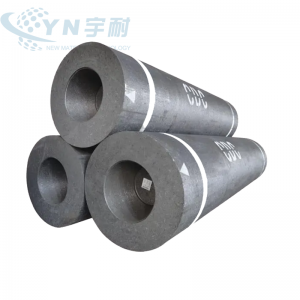

ultra high power graphite electrode

Uses and properties of graphite electrodes:

1. Used in electric arc steelmaking furnace

Graphite electrodes are mainly used in electric furnace steelmaking. Electric furnace steelmaking is to use graphite electrodes to introduce current into the furnace. The strong current passes through the gas at the lower end of the electrodes to generate arc discharge, and the heat generated by the arc is used for smelting. According to the capacity of the electric furnace, graphite electrodes with different diameters are used. In order to make the electrodes use continuously, the electrodes are connected by electrode threaded joints. Graphite electrodes for steelmaking account for about 70-80% of the total amount of graphite electrodes.

2. Used in submerged heat electric furnace

Graphite electrode submerged thermal electric furnace is mainly used to produce ferroalloy, pure silicon, yellow phosphorus, matte and calcium carbide, etc. It is characterized in that the lower part of the conductive electrode is buried in the charge, so in addition to the heat generated by the arc between the electric plate and the charge, the current Heat is also generated by the resistance of the charge when it passes through the charge. Each ton of silicon needs to consume about 150kg of graphite electrodes, and each ton of yellow phosphorus needs to consume about 40kg of graphite electrodes.

3. Used in resistance furnace

Graphitization furnaces for the production of graphite products, melting furnaces for melting glass, and electric furnaces for the production of silicon carbide are all resistance furnaces. The materials in the furnace are both heating resistors and objects to be heated. Usually, graphite electrodes for conduction are inserted into the burner wall at the end of the hearth, so that the conduction electrodes are not continuously consumed.

4. For processing

A large number of graphite electrode blanks are also used to process various shaped products such as crucibles, graphite boats, hot pressing molds and heating elements of vacuum electric furnaces. It should be noted that there are three types of synthetic materials for graphite materials at high temperatures, including graphite electrodes, graphite molds and graphite crucibles. Graphite in these three materials is prone to oxidative combustion reactions at high temperatures, resulting in a carbon layer on the surface of the material. Increased porosity and loose structure affect service life.

Graphite electrodes are mainly made of petroleum coke and needle coke, and coal tar pitch is used as a binder. They are made by calcination, batching, kneading, pressing, roasting, graphitization, and machining. They release electric energy in the form of arcs in electric arc furnaces. The conductors for heating and melting the charge can be divided into ordinary power graphite electrodes, high power graphite electrodes and ultra-high power graphite electrodes according to their quality indicators.

Quote Now

Quote Now