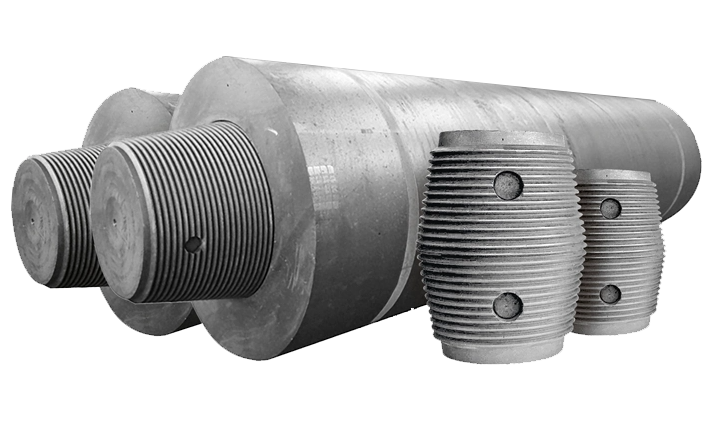

UHP Graphite Electrode with Nipples

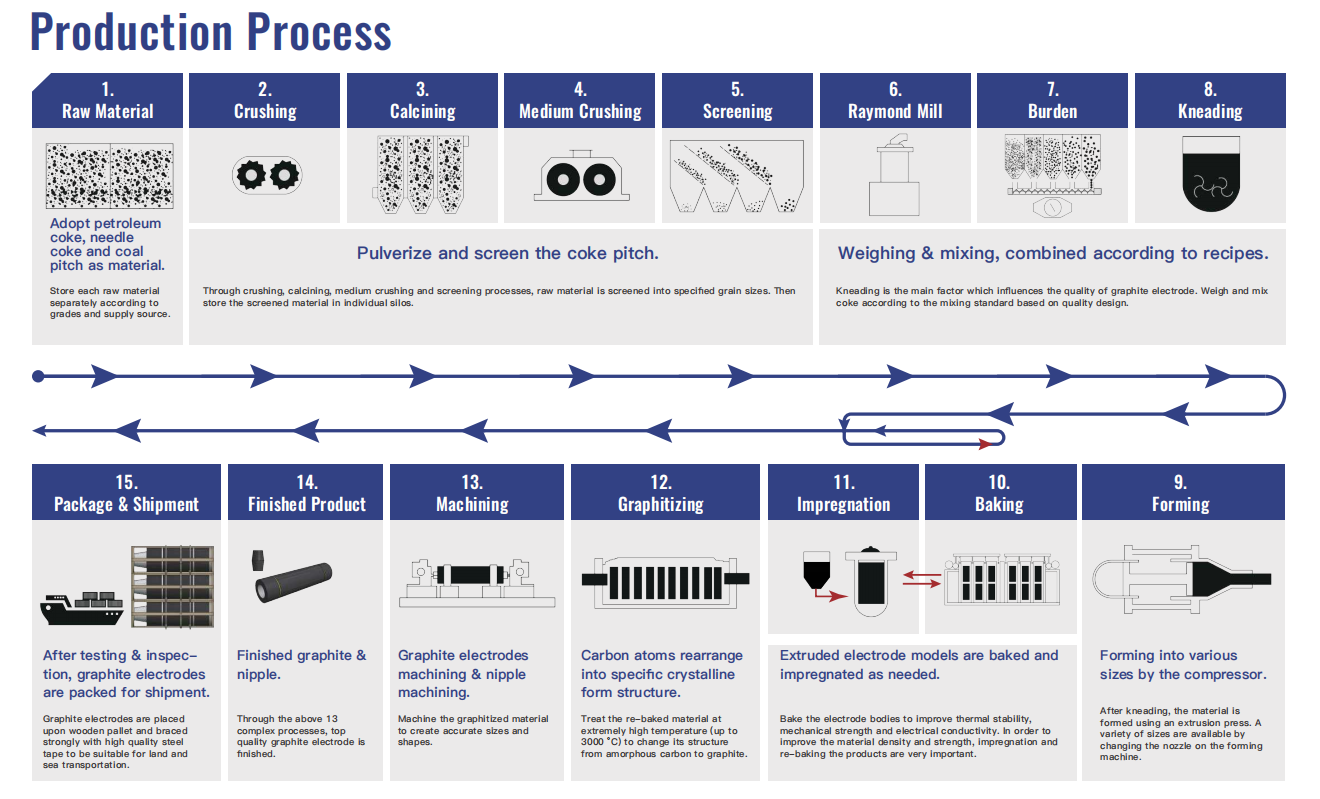

1. Introduction :

UHP graphite electrode is used for steel recycling in electric arc furnace industry. Its main component is high-value needle coke, which is made of petroleum or coal tar. The graphite electrode is machined in a cylindrical shape and a threaded area is machined at each end. In this way, the graphite electrode can be assembled into an electrode column using an electrode connector.

In order to meet the requirements of higher work efficiency and lower total cost, large capacity ultra-high power arc furnace is becoming more and more popular. Therefore, UHP graphite electrodes with a diameter of more than 500 mm will dominate the market

2. Features

- High current resistance and high discharge rate.

- Good dimensional stability and not easy to deform.

- Resistance to cracking and spalling.

- High oxidation resistance and thermal shock resistance.

- High mechanical strength and low resistance.

- High machining precision and good surface finish.

- Uniform structure, good conductivity and thermal conductivity

3. Application

Graphite electrode is widely used in the production of alloy steel, metal and other non-metallic materials.

DC electric arc furnace.

AC arc furnace.

Submerged arc furnace.

Ladle furnace.

(1) Regular power graphite electrode

It is allowed to use graphite electrode with current density lower than 17a / cm2, which is mainly used in ordinary power electric furnaces for steelmaking, silicon smelting, yellow phosphorus smelting, etc.

(2) Oxidation resistant coated graphite electrode

Graphite electrode coated with a layer of antioxidant protective layer (graphite electrode antioxidant). Form a protective layer that can conduct electricity and resist high-temperature oxidation, reduce the electrode consumption during steelmaking (19% ~ 50%), prolong the service life of the electrode (22% ~ 60%), and reduce the electric energy consumption of the electrode. The popularization and use of this technology can bring such economic and social effects:

① The unit consumption of graphite electrode is less, and the production cost is reduced to a certain extent. For example, in a steelmaking plant, based on the consumption of 35pcs graphite electrodes per week and 165 refining furnaces in the primary LF refining furnace without shutdown throughout the year, 373pcs graphite electrodes can be saved every year after the graphite electrode oxidation resistance technology is adopted

(153 tons) electrode, calculated at 3000USD per ton of ultra-high power electrode per year, USD 459,000 can be saved.

② The graphite electrode consumes less power, saves the unit steelmaking power consumption, saves the production cost and saves energy!

③ Because the graphite electrode is changed less times, the amount of labor and risk coefficient of operators are reduced, and the production efficiency is improved.

④ Graphite electrode is a low consumption and low pollution product. Today, when energy conservation, emission reduction and environmental protection are advocated, it has very important social significance.

This technology is still in the research and development stage in China, and some domestic manufacturers have also begun to produce it. It has been widely used in Japan and other developed countries. At present, there are also companies specializing in importing this anti-oxidation protective coating in China.

(3) High power graphite electrode. Graphite electrode with current density of 18 ~ 25A / cm2 is allowed to be used, which is mainly used in high-power electric arc furnace for steelmaking.

(4) Ultra high power graphite electrode. UHP Graphite electrodes with a current density greater than 25A / cm2 are allowed. It is mainly used for ultra-high power steelmaking electric arc furnace.

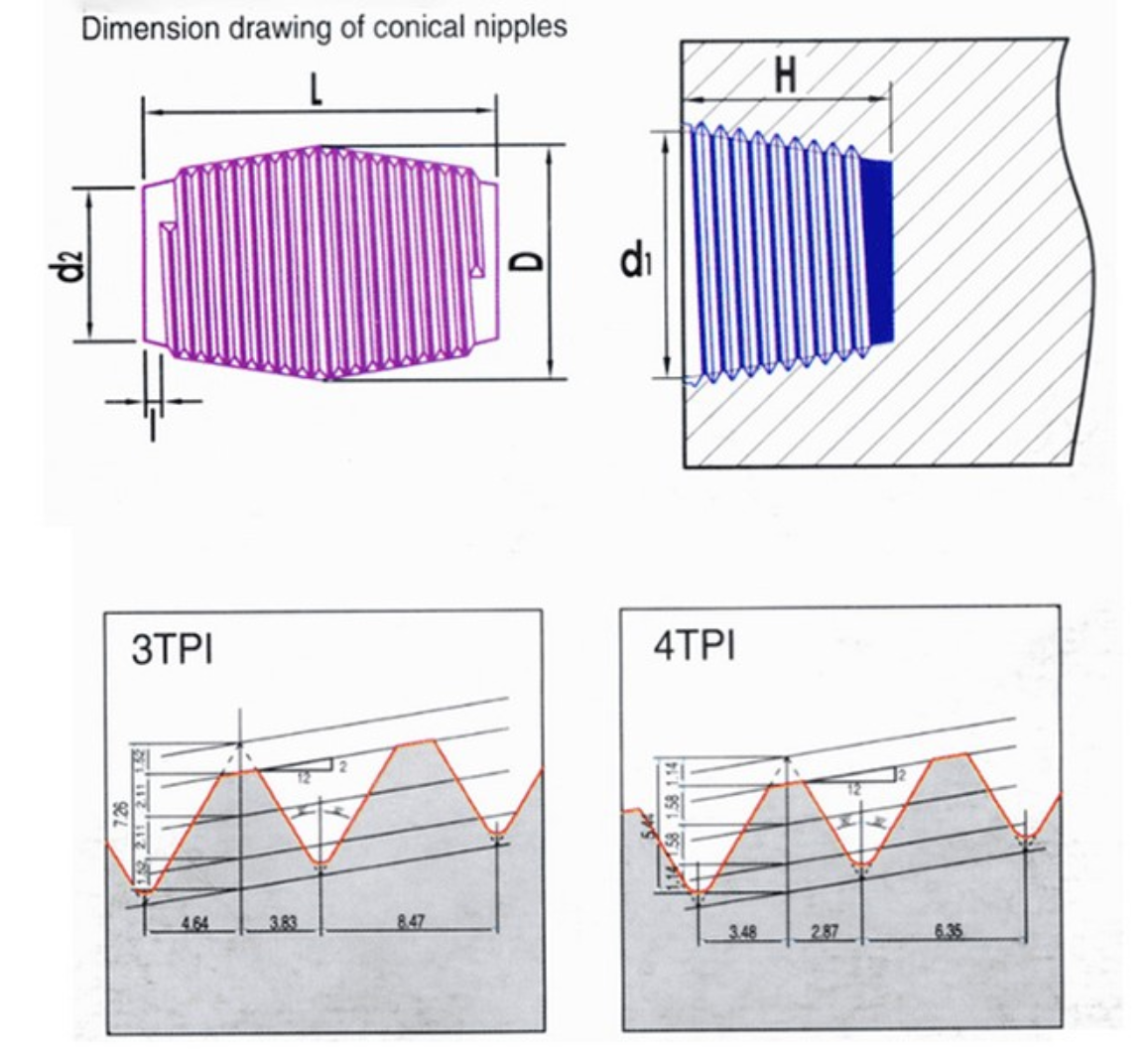

4. Nipple

3TPI/T4L/T4N Or Customized

5. Product Parameters

Graphite Electrode More specification and Details :

For following just for your reference :

| Items | Regular power(RP) | High power(HP) | Ultrahigh power(UHP) | |||||||

| ⌽200-300 | ⌽350-600 | ⌽700 | ⌽200-400 | ⌽450-600 | ⌽700 | ⌽250-400 | ⌽450-600 | ⌽700 | ||

| ResistanceμΩm(Max) | Electrode | 7.5 | 8.0 | 6.5 | 7.0 | 5.5 | 5.5 | |||

| Nipple | 6.0 | 6.5 | 5.0 | 5.5 | 3.8 | 3.6 | ||||

| BulkDensityg/cm3(Min) | Electrode | 1.53 | 1.52 | 1.53 | 1.62 | 1.60 | 1.62 | 1.67 | 1.66 | 1.66 |

| Nipple | 1.69 | 1.68 | 1.73 | 1.72 | 1.75 | 1.78 | ||||

| BendingStrengthMpa(Min) | Electrode | 8.5 | 7.0 | 6.5 | 10.5 | 9.8 | 10.0 | 11.0 | 11.0 | |

| Nipple | 15.0 | 15.0 | 16.0 | 16.0 | 20.0 | 20.0 | ||||

| Young’smodulusGpa(Max) | Electrode | 9.3 | 9.0 | 12.0 | 12.0 | 14.0 | 14.0 | |||

| Nipple | 14.0 | 14.0 | 16.0 | 16.0 | 18.0 | 22.0 | ||||

| Ash%(Max) | Electrode | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 | 0.3 | |||

| Nipple | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 | 0.3 | ||||

| CTE(100-600℃)×10-6/℃ | Electrode | 2.9 | 2.9 | 2.4 | 2.4 | 1.5 | 1.4 | |||

| Nipple | 2.8 | 2.8 | 2.2 | 2.2 | 1.4 | 1.2 | ||||

Standard Sizes of Electrode :If there are special specification requirements,both sides consult supply & demand.

For more detailed Sizes and Specs : Uhp Graphite electrode , Graphite electrodes , Hp Graphite Electrode , Rp Graphite electrode φ200mm-700mm Length 1800mm -2700mm

| Standard sizes of electrode | ||||||

| Specifications(inch) | Allowable Diameter(mm) | Allowable Length(mm) | ||||

| Nominal Diameter | Max. | Min. | Nominal Length | Max. | Min. | |

| 6 | 150 | 154 | 151 | 1600 | 1700 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 8 | 200 | 205 | 200 | 1600 | 1700 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 9 | 225 | 230 | 225 | 1600 | 1700 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 10 | 250 | 256 | 251 | 1600 | 1700 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 12 | 300 | 307 | 302 | 1800 | 1875 | 1700 |

| 14 | 350 | 357 | 352 | 1600 | 1700 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 16 | 400 | 409 | 403 | 1600 | 1500 | 1500 |

| 1800 | 1875 | 1700 | ||||

| 2100 | 2175 | 1975 | ||||

| 18 | 450 | 460 | 454 | 1800 | 1875 | 1700 |

| 2100 | 2175 | 1975 | ||||

| 2400 | 2475 | 2275 | ||||

| 20 | 500 | 511 | 505 | 1800 | 1875 | 1700 |

| 2100 | 2175 | 1975 | ||||

| 2400 | 2475 | 2275 | ||||

| 22 | 550 | 562 | 556 | 2100 | 2175 | 1975 |

| 2400 | 2475 | 2275 | ||||

| 24 | 600 | 613 | 607 | 2100 | 2175 | 1975 |

| 2400 | 2475 | 2275 | ||||

| 2800 | 2850 | 2550 | ||||

| 28 | 700 | 714 | 708 | 2400 | 2475 | 2275 |

| 2800 | 2850 | 2550 | ||||

Current Carrying Capacity for Graphite Electrode:

| Nominal Diameter(mm) | Regular Power | High Power | Ulra High Power | |||

| Current Load(A) | Current Density(A/cm2) | Current Load(A) | Current Density(A/cm2) | Current Load(A) | Current Density(A/cm2) | |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ———— | ———— |

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ———— | ———— |

| 250 | 7000~10000 | 14-20 | 8000~13000 | 18-25 | ———— | ———— |

| 300 | 10000~13000 | 14-18 | 13000~17400 | 17-24 | 15000~22000 | 20-30 |

| 350 | 13500~18000 | 14-18 | 17400~24000 | 17-24 | 20000~30000 | 20-30 |

| 400 | 18000~23500 | 14-18 | 21000~31000 | 16-24 | 25000~40000 | 19-30 |

| 450 | 22000~27000 | 13-17 | 25000~40000 | 15-24 | 32000~45000 | 19-27 |

| 500 | 25000~32000 | 13-16 | 30000~48000 | 15-24 | 38000~55000 | 18-27 |

| 550 | 32000~40000 | 13-16 | 37000~57000 | 15-23 | 42000~66000 | 17-26 |

| 600 | 38000~47000 | 13-16 | 44000~67000 | 15-23 | 49000~88000 | 17-26 |

| 700 | 48000~59000 | 12-15 | 59620~83600 | 13-18 | 70000-110000 | 17-24 |

Quote Now

Quote Now